Capturing over 700 horsepower from a small block chevy is no easy task. In this post we’re going to show you how a handful of companies have created engines that have eclipsed 700 hp. This could help shed some light on the factors for you to be high horsepower on your future build.

Why not push your car to the absolute limit? Simply, because you want to live as long as possible! That’s why I built an engine capable of 700 hp. There are four reasons I wanted to build a 700 hp engine: 1) Because I can 2) Because my friends can’t 3) It will be fun 4) For bragging rights.

How to build a 700 hp small block chevy

The best way to build a 700hp small block Chevy is to start with a clean slate. I would recommend building the motor from scratch, which means you’ll need to buy all new parts.

If you’re looking for a turnkey solution, then I would recommend purchasing a crate motor. This will come with everything you need including the block, crankshaft, connecting rods and pistons. You’ll still have to purchase your own camshaft, valvetrain components and timing set.

If you’re looking for something more specific, then there are many options available that can help you achieve your desired power goal. Here’s an overview of some of the most popular combinations:

500hp SBC Build Sheet: This is a great starting point if you want to keep it simple without sacrificing much power or reliability. You’ll be able to make this combination in any budget range but it will require extensive tuning and modification for maximum performance.

We’ve compiled a list of the best 700 hp Small Block Chevy builds, including dyno results and videos.

There are many different ways to achieve 700 hp from a small block Chevy, but we’ve chosen what we think is the most reliable and proven combo for this build sheet.

A 700hp small block Chevy will give you more than enough power to win local drag races, cruise down the highway or put on some serious smoke at the track.

Small Block Chevrolet Performance Parts

Bolt Ons: Headers + Intake + Exhaust + Camshaft + Carburetor + Ignition

Engine Build: Stroker Crank + Pistons + Rods/Bearings + Valvetrain/Heads/Rocker Arms/Valves/Camshafts

The 700 hp small block chevy build sheet is a great way to get the most out of your engine. This is an affordable and powerful build that is perfect for any street or strip application.

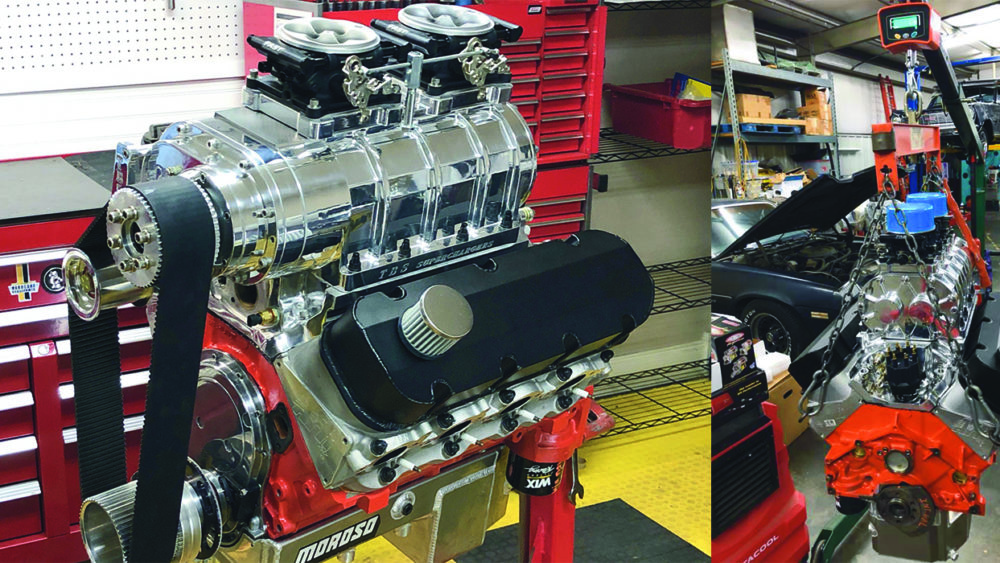

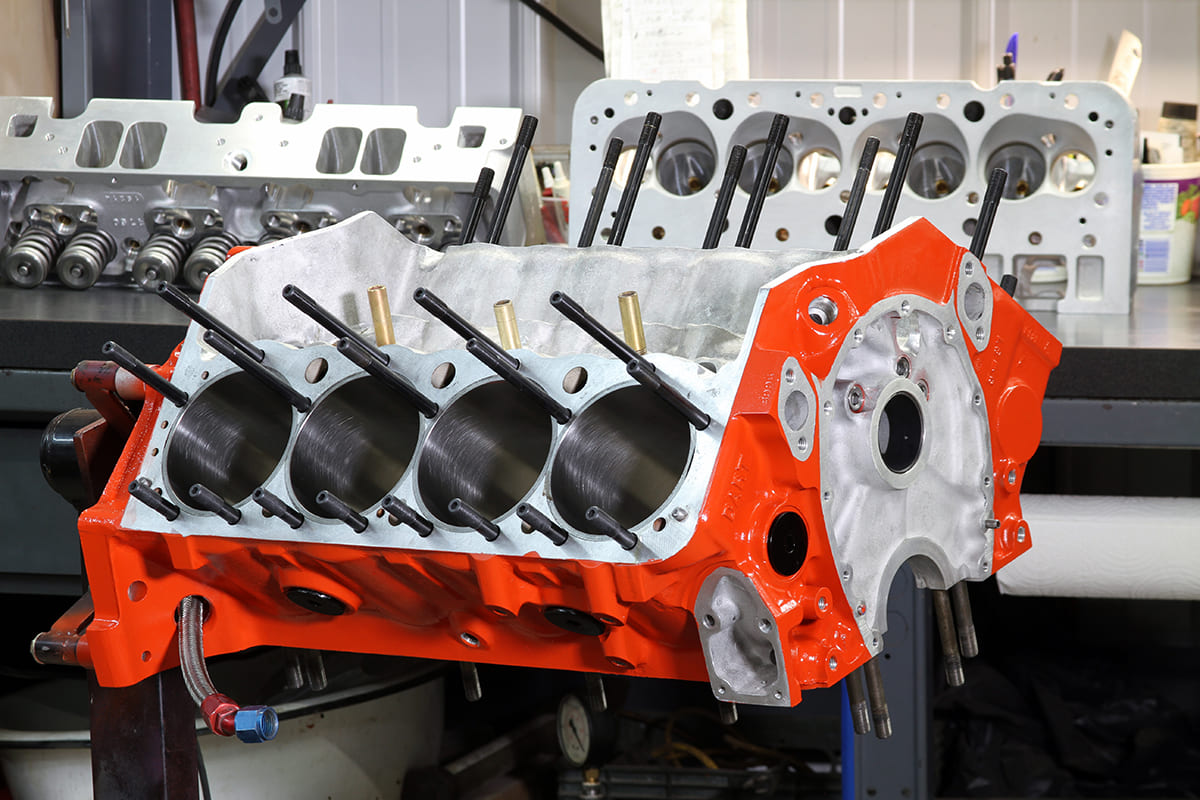

This build starts with a Dart SHP block that has been bored to 4.030”, decked and line honed with a 10mm head gasket bore for added strength and durability. The Dart SHP block uses 9/16” head studs to maximize clamping force on the cylinder heads. To help keep the rotating assembly from flexing under extreme conditions, we installed forged Eagle H-beam rods and Mahle pistons with a 9:1 compression ratio.

The rotating assembly is topped off with a set of Callies Magnum XL connecting rods and ARP fasteners for increased clamping force over OE components. A set of custom Diamond Racing Pistons rings round out this impressive package and ensure proper sealing under high RPM conditions.

The bottom end is filled with a Moroso oil pan, Moroso pick up tube kit and Fel Pro 1 piece rear main seal/pan gasket set to prevent unwanted leaks from occurring during hard launches or track sessions.

SBC 700 HP Build Sheet:

Parts List:

*Forged connecting rods (Part No. 8045)

*ARP rod bolts (Part No. ARP-61700)

*Kurt Rethwisch billet aluminum oil pump (Part No. 7660)

*Kurt Rethwisch billet oil pan (Part No. 7690)

*Kurt Rethwisch billet timing cover (Part No. 7750)

*ARP main stud kit for billet oil pan, includes ARP hardware and ARP studs with nuts, washers, and sealer (Part No. 6300) or use a set of good quality bolts like those from ARP or similar company that uses grade 8 fasteners; don’t use cheap hardware store bolts! The billet covers are designed to accept either studs or bolts but they have tapped holes so they can be bolted together if necessary, but studs are preferred because they are easier to install than bolts and they have better clamping force over a wider area than a bolt head would have; other manufacturers sell different versions of this same idea in their products so you can probably put together your own kit using parts from different manufacturers

This is a list of the top three most common small block Chevy engine builds. The idea was to show how much power can be made with a stock block and some bolt-ons.

Unfortunately, the world of high performance engines is filled with misinformation and myths. Fortunately, there are plenty of people who have done their research and have great information to share.

Here are some of my favorite sites for learning about building big blocks:

Chevrolet Performance – This site has been around for years and has a ton of useful information for anyone interested in building or modifying their own Chevy engine.

Edelbrock – Another classic site that has been around for decades. They have plenty of articles and videos on building big blocks as well as other types of engines like LS engines and Small Blocks.

500 horsepower small block Chevy engine build sheet.

A 500 horsepower, 383 stroker small block Chevy is the perfect motor for a mildly modified car or truck. When you’re ready to upgrade to a big block, this is an ideal starting point!

1000 horsepower small block chevy build sheet.

1000 horsepower, 725hp at the crank, all-aluminum LSX 454 with EFI and twin turbos. This is the ultimate muscle car motor!

700 horsepower 421 sbc build sheet.

700 horsepower, 585hp at the crank small block Chevy engine build sheet. The perfect combination of power and reliability.

500 hp small block chevy build sheet:

We can build a 500hp small block Chevy in your choice of 2 or 4 bolt main. This motor is designed for street use and has a nice flat torque curve to keep you in the power band. We also offer this motor with a hydraulic roller camshaft which will add some extra ponies and torque. The valvetrain is done with roller rockers and adjustable pushrods for superior performance at high RPM’s.

This motor is perfect for any street rod or muscle car that requires a reliable power plant without breaking the bank!

PARTS LIST:

ARP head studs – $575

ARP Main Stud Kit – $305

Comp Cam Xtreme Energy 264H cam – $600

Heads – $500 (AED) 4V, 0.030″ overbore, 10cc lower dome pistons, Brodix heads # BC6061, 3 angle valve job on both intake and exhaust side, 1.5 ratio roller rockers (1/2″ shaft diameter), springs & retainers, timing cover gaskets, oil pump pickup tube seal kit (included but not shown). All parts are available from www.brodixperformance.com . Other options may be

The Small Block Chevy was introduced in 1955 and continued production until the end of the 1999 model year. The engine was replaced by a new line of engines known as LS-Series, but the name is still widely used to refer to engines based on the original small block design. The engine is known for its durability and power.

The small block Chevy has been installed in many vehicles including trucks, cars, vans and SUVs. It is also available as a crate motor for use in drag racing or other motorsport applications.

A number of different versions of this engine were produced over the years with various displacements, cylinder counts and power output levels.

Some versions include:

350ci (5.7L) – This was an early version that did not have hydraulic lifters; instead it had solid lifters which meant that they would need to be adjusted manually at regular intervals to avoid damage to the camshafts. This version was produced from 1955 to 1961 with a bore diameter of 3 inches (76mm) and stroke length of 4 inches (102mm). The 350ci SBC had a maximum power output of 140hp at 4200rpm and torque rating of 240 lb-ft at 2800rpm

The small-block Chevy is an American icon of performance, and one of the most popular engines in history. The small-block is also a great choice for a crate motor build, especially when you need more power than stock.

Here are some of the best 600-hp crate engines available on the market today:

Edelbrock Performer RPM Air-Gap LS Crate Engine – This 600-horsepower crate engine features a forged steel crankshaft and connecting rods, high-performance aluminum heads, and a forged steel camshaft with roller lifters. It’s also ready to use with a plug & play wiring harness and comes with an MSD distributor that has been set up for easy installation.

Chevrolet Performance LSX 454 Crate Engine – This 700-horsepower crate engine features a cast iron block and rotating assembly that has been balanced for smooth operation. It also comes with an aluminum cylinder head that’s been CNC ported for maximum airflow, along with an overhead valve camshaft and hydraulic roller lifters from Chevrolet Performance that offer maximum valve lift at .580 inches.

Chevy Performance LSX 572 Crate Engine – This 745-horsepower crate motor features a forged steel crankshaft

The small block Chevy is the most famous and successful V8 engine in the history of GM. It is the most produced, the most raced and has won more championships than any other engine family. The small block was designed by Ed Cole, first as a 283 cubic inch (4.6 L) version in 1955 for use in Cadillac’s new luxury car, then as a larger displacement 355 in 1956 for Chevrolet’s new luxury car, the Bel Air Impala. The third generation 283 was produced from 1968 through 1970 when it was replaced by the 350 which was introduced in 1969.

The fourth generation 283 was produced from 1971 through 1986 with few changes other than displacement increases over time to 307 cid (5.0 L), 327 cid (5.3 L), 350 cid (5.7 L) and displacements as large as 400 cid (6.6 L). In 1979 there were some minor changes including an increase of compression ratio to 9:1 on all engines except High Performance 350 and 400 which retained 10:1 compression ratio due to their limited production nature. The camshaft was also changed from hydraulic to solid tappet design whereby the camshaft lobe rides directly against a lifter surface rather than a roller type.